Injector Dynamics BPC100

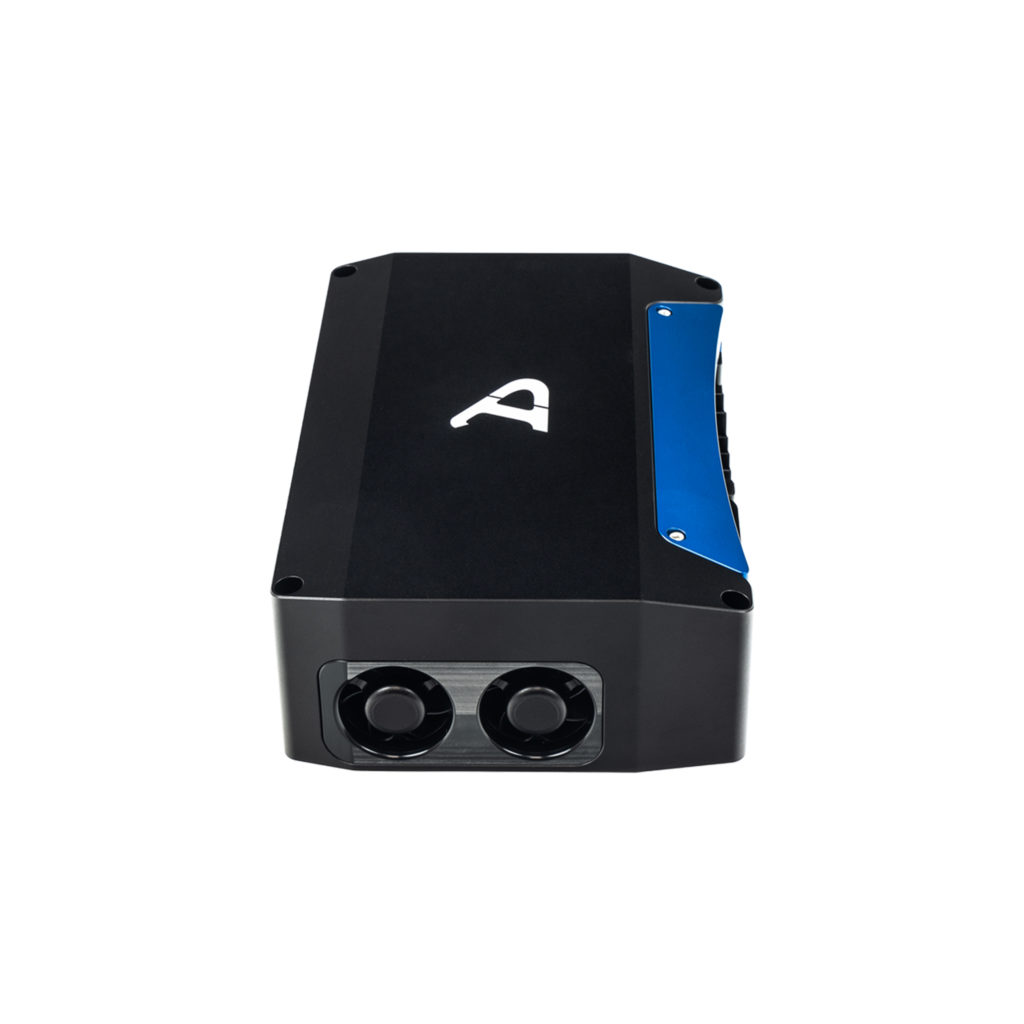

The injector dynamics fuel pump controller (BPC100), a 100-amp brushless unit, is designed for use with the TI E5LM fuel pump.

Injector Dynamics BPC100 – The Single Pump Solution

The BPC100 mated to the TI Automotive E5LM brushless pump represents a new approach to fueling high power racing engines – providing enough fuel for 2000+ hp on ethanol at pressures as high as 150 psi from a single pump.

How Does it Work?

The BPC100 is a microprocessor-based pump controller which monitors pump speed and maintains a target flow rate even as operating conditions change. It does so by powering the pump from an internal power supply, making pump flow independent of battery voltage and fuel pressure across a broad operating range.

This is in sharp contrast to conventional designs where flow is a function of system voltage and fuel pressure. Consider that while a pair of 500 l/h conventional pumps may flow a combined total of 1,000 l/h at 3 bar and 13.5 volts, this can drop as low as 700 l/h at 30 psi of boost. That same 30 psi of boost at 4 bar static pressure and 12.0 volts reduces the flow even further, as low as 500 l/h – less than half the advertised value.

Note that this is not a defect, or misleading marketing, it is simply the nature of conventional pumps. In comparison, the BPC100 is capable of maintaining 1,100 l/h under the conditions above, and more. How about 5 bar static pressure, and 5 bar boost with a broken alternator belt and a failing battery delivering only 8 volts at the 1320?

Still…1,100 l/h!

For detailed specifications, installation guide and troubleshooting manual click here

*CONTROLLER ONLY, NO PUMP INCLUDED*

For the Injector Dynamics FPS1100 (controller and pump) click here!

Details

Standard Functions

| Flow Rate Control | Fixed Flow Rate by Onboard Potentiometer Variable Flow Rate by MAP Sensor Real Time Flow Rate Control by PWM Input |

| Troubleshooting | Error code reporting by onboard LED array Error code transmission by CAN bus |

| CAN Communication | System Voltage Current Draw Flow Rate Operating Temperature MAP Voltage PWM Duty Cycle |

Basic Operating Specifications

| Operating Voltage: | 7.0 to 17.5 volts DC (w/ Reverse Polarity Protection) |

| Pressure | 150psi Maximum |

| Flow Rate | Variable – From 400 l/h – 1,100 l/h |

| Current Draw – Dependent on Operating Conditions: | 5 amp minimum 100 amp maximum |

| Ambient Temperature Range: | -18°C to 70°C |

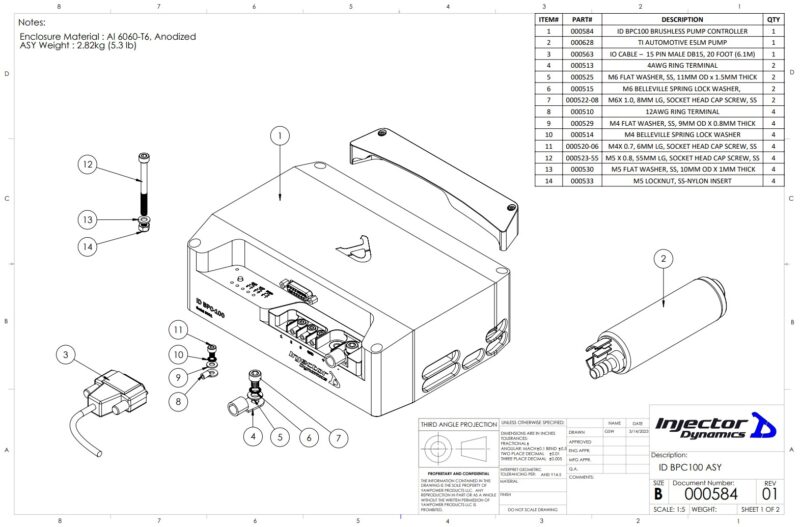

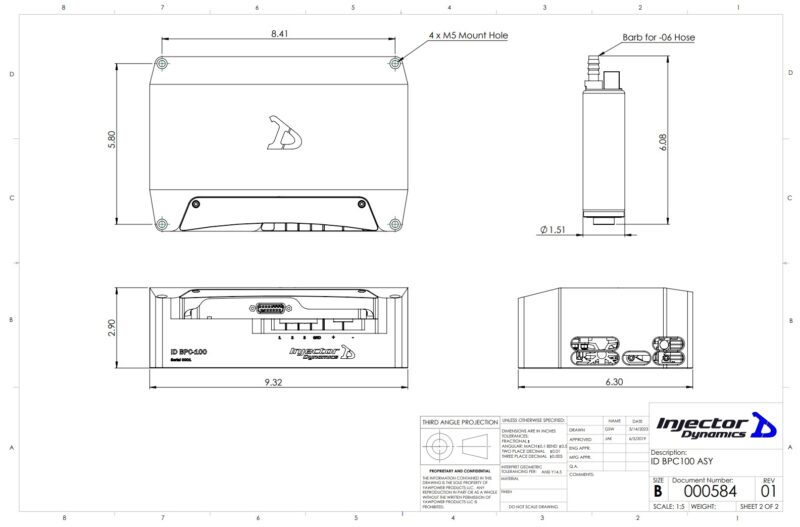

Dimensions

Frequently Asked Questions About Injector Dynamics Fuel Pump Controller

What is the main function of the injector dynamics fuel pump controller?

The injector dynamics fuel pump controller (BPC100) regulates the speed of the brushless pump to maintain a target flow rate, ensuring consistent fuel delivery regardless of battery voltage fluctuations.

Which fuel pump is compatible with the BPC100?

The BPC100 controller is specifically designed to be mated with the TI Automotive E5LM brushless fuel pump for maximum efficiency and flow.

How much horsepower can the injector dynamics fuel pump controller support?

When paired with the E5LM pump, the injector dynamics fuel pump controller can support over 2000+ HP on ethanol, delivering flow at pressures as high as 150 psi.

Does low battery voltage affect the BPC100's performance?

No. Because the BPC100 uses an internal power supply, it can maintain full flow (1,100 l/h) even if the vehicle's battery voltage drops as low as 8 volts during a pass.

How does this system compare to dual conventional pumps?

Conventional pumps lose flow as boost increases and voltage drops. The BPC100 system maintains consistent flow independent of pressure and voltage, often outperforming dual 500 l/h pumps under load.

Comments & Reviews